|

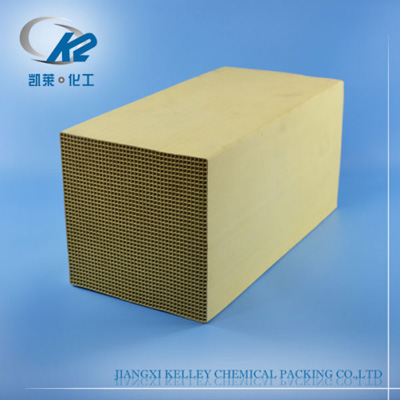

Honeycomb ceramic regenerators enhance efficiency, save energy, increase output and improve quality, an important and effective measure when dealing with energy and the environment. They're applied on thermal equipment for energy saving within industry. The pores of the Honeycomb ceramic regenerators are square and hexagonal, and the channels of pores are straight and parallel to each other. This structure reduces the resistance of passing air and enhances the heat exchange efficiency of every channel. 1. Reduce the thermal loss of exhaust gas, and improve the efficiency of fuel to save energy as. 2. Enhance the burning temperature based on theory, improve the atmospheric burning, meet the high temperature of thermal equipment enlarge low calorific value fuel, especially the application range of blast furnaces, improve the efficiency of calorific value fuel and reduce...

|

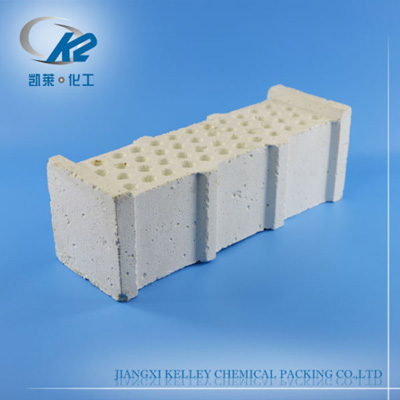

Honeycomb protective blocks are also named as "baffle bricks" in China. In regenerative furnace (such as RTO application), they are installed in front of honeycomb ceramics to protect honeycomb ceramics and extend the life of them. So the first thing to consider is their high-temperature property and thermal shock resistance. KELLEY's honeycomb protective blocks, with white fused alumina as the main raw material, are of fine high temperature stability and excellent thermal shock resistance effect. Using our white fused alumina blocks, you can double the using life of honeycomb ceramics; significantly reduce the downtime of plant and production costs...